CNC PANEL SAW

CNC PANEL SAW

Model: SMHH 280

|

Specifications

|

|

|

Max cutting length

|

: 2800 mm

|

|

Max cutting thickness

|

: 100 mm

|

|

Main saw blade diameter

|

: φ 380/400 mm

|

|

Main saw shaft diameter

|

: φ 60 mm

|

|

Main saw shaft rotation speed

|

: 4000 rpm

|

|

Scoring saw blade diameter

|

: φ 180 mm

|

|

Scoring saw shaft diameter

|

: φ 30mm

|

|

Scoring saw shaft rotation speed

|

: 6900 rpm

|

|

Saw carriage forward speed

|

: 100 m/min

|

|

Saw carriage backward speed

|

: 120 m/min

|

|

Main saw motor

|

: 16 kW

|

|

Saw carriage drive motor

|

: 2.2 kW

|

|

Automatic feeding motor

|

: 1 kW

|

|

High-pressure blower motor

|

: 3 kW

|

|

Total power

|

: 22.2 kW

|

|

Automatic feeding speed

|

: 100 m/min

|

|

Air pressure

|

: 5-7 kg/cm2

|

|

Worktable height

|

: 960 mm

|

|

Net weight

|

: 4500 kg

|

|

Machine size

|

: 5300 x 6300 x 2000 mm

|

|

Number of air floats

|

: 3

|

|

Machine structure

|

|

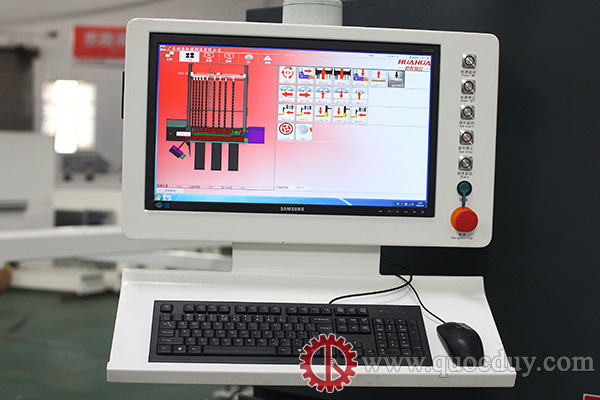

20'' PC control system 20'' PC control system1. Easy operation, safety & reliable.

2. Which has complete operating hints and troubleshooting guide functions.

3. It’s cutting plan can edit manually; can simulate or execute cutting plans.

4.Can compatible with bar code manage software or factory automation software.

|

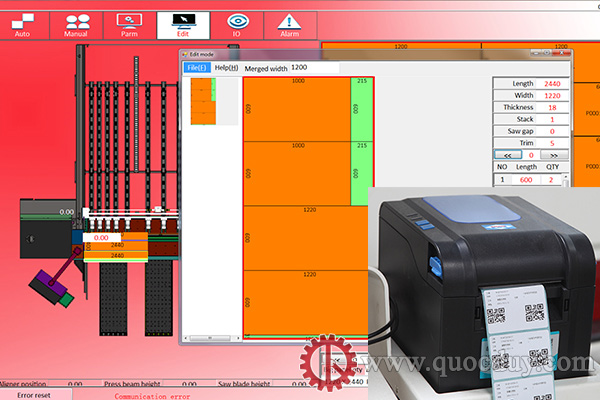

Cutting optimization software and laber Printer Cutting optimization software and laber PrinterOptimization software: Automatically generate the optimazation sawing solution, can save personal calculation time and enhancing material utilization efficiency, which can save labor cost, material and inhance the efficiency.

Label printer: one cutting board stick one label with all information on the label, such like customer name, board name, board thickness, width, length, easy for factory to control production.

|

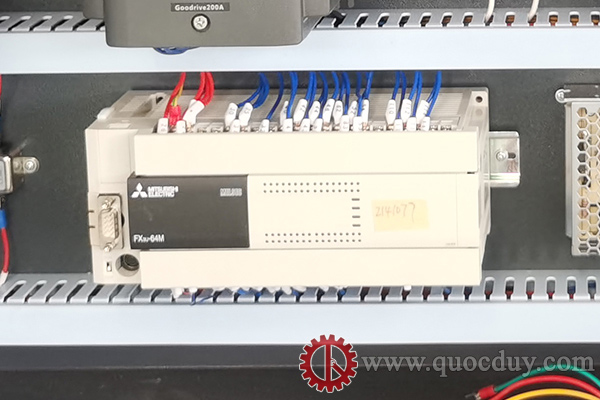

PLC PLCJapan Mitsubishi PLC control system.

|

Side aligning device Side aligning deviceFix cutting panel width side, control panels not move or shake when sawing, ensure width sawing precision. Pressure can be adjusted according to difference thickness, weight and material, ensure the precision of sawing dimension.

|

Main steel frame Main steel frameMain surface bending by 22mm thick steel, adopting advanced CO2 gas shielded arc welding technology, ensure frame non-deformation, high efficiency and stable quality.

|

Lubricating system Lubricating systemAuto lubricating for machine body, very convenient, can prolong the machine’s service life and keep good accuracy

|

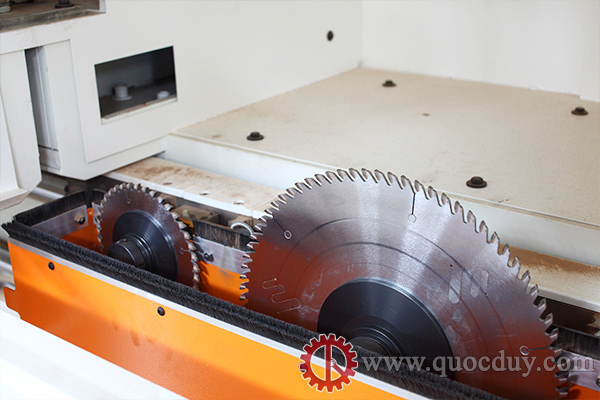

Saw blades Saw blades1). Two saw blades ensure cutting precision.

2). Main saw blades 16HP, max cutting thickness: 100mm.

3). Saw blades gears: Germany SKF;

4). Sawing motor: TAIWAN SANYE;

|

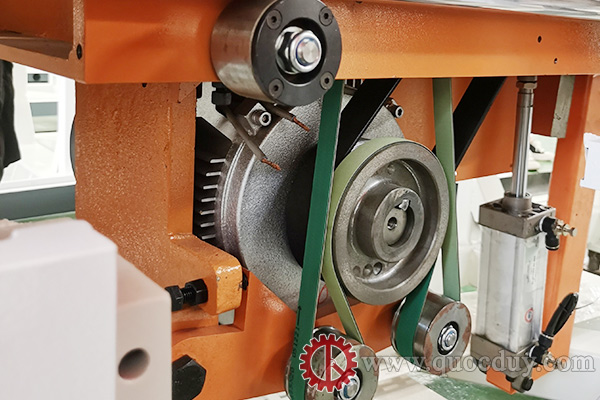

Saw carrier Saw carrier 1). Driven by imported TAIWAN FENGMAO high-precision rack & pinion, stable movement, ensure cutting precision.

2). Saw carrier pull back position automatically controlled base on next cutting length, Which reduce unused moving time and greatly improve efficiency.

3). Max cutting speed reach to 100m/min.

|

Loading system Loading systemAir floating loading table,avoiding board scratching and assuring smoother board movement, suit for heavy and big type wood panel.

|

Feeding gripper Feeding gripperEquip 7pcs pneumatic holding gripers, can gripe the panel steadily, highly reduce labor intensity, and greatly improve production efficiency, Min holding panel size 45mm.

|

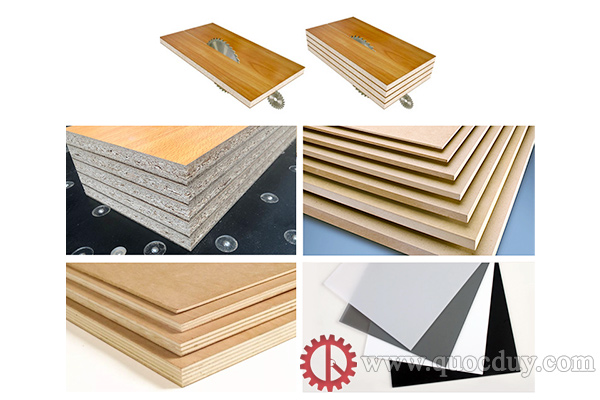

Plank Plank |

Finished product Finished product |